Activities

powertrain assembly in park

park maintenance and repairs

transport and management of components

in-plant repair and quality control

Presentation

SINCRO MECÁNICA was founded in 2009 as a company specialising in the comprehensive maintenance of wind turbine power trains.

SINCRO MECÁNICA‘s differentiation is focused on its ability to develop a specialised service that integrates all phases of the value chain in the maintenance of the power train, where reliability and effectiveness in response, process efficiency, agility and flexibility are the strategic principles of our performance.

SINCRO MECÁNICA is equipped with the infrastructures and the technical, human and technological resources necessary to provide a differentiating service, strongly aligned with the interests of the client.

Services

A) Park Service:

- Predictive maintenance.

- Condition assessment.

- Disassembly, repair, assembly, commissioning and monitoring of power train indicators.

B) Plant Service:

- Initial condition assessment.

- Disassembly and traceability.

- Cleaning of components.

- Inspection and condition control.

- Component logistics management.

- Assembly.

- No load and load test.

- Shipment/shipment preparation. Intervention report.

C) Engineering services:

- Technical study of equipment.

- Development of maintenance solutions.

Services

Capacities

- Lifting capacity up to 50 t.

- Six production units with their own lifting capacity.

- More than 5,500 m² of floor space.

- More than 2,000 m² available for storage of components, spare parts and work in progress.

- Coordinate measurement up to 1,600 x 2,400 x 1,400 mm, with a nominal maximum permissible error of 3.5 + L / 250μm (DIN-EN ISO 10360), with an actual deviation in calibration of ± 1.0 μm.

- Six-axis articulated arm with spherical working volume of 2.4 m. Accuracy of ± 0.025 mm in volumetric and ± 0.018 mm in single point.

- Load test up to 1.5 MW at 100% load and 3 MW at 50% load.

- Standard oil cleanliness level: 16/15/12, according to ISO 4406.

- Spray and ultrasonic cleaning of components.

- Field vibration analysis and remote visual inspection.

- Shaft alignment.

- Non-destructive testing.

- Induction heating system.

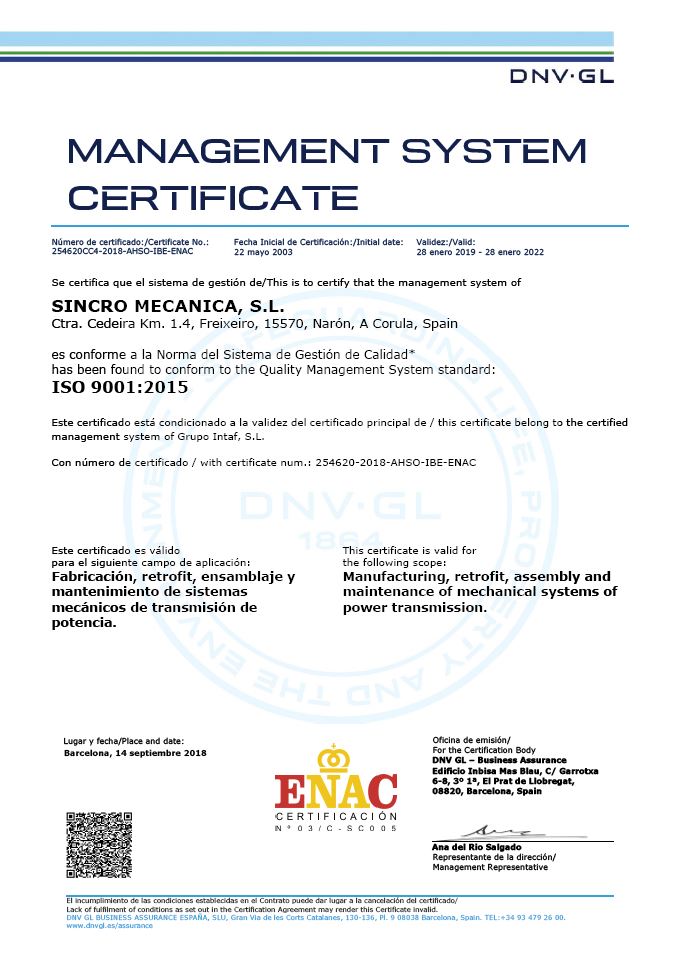

Accreditations

Convinced of the importance of innovation and the optimisation of management efficiency and effectiveness, and applying a firm focus on the customer and processes, INTAF PROMECAN has developed and implemented a Management System in which three core aspects of the activity coexist in an integrated manner: quality, environment and occupational risk prevention.

This system has been developed based on the following standards:

- UNE-EN ISO 9001

- UNE-EN ISO 14001

- OHAS 18001

- It has been certified by Det Norske Veritas, an accredited certification body.

News

GRUPO INTAF supports the maintenance of an icon of Ferrol and its region in the Navantia Shipyard, the Gantry Crane

Tecman Maintenance and Services, a company belonging to the Intaf Group, collaborates with Navantia in the maintenance of one of the icons of Ferrol and the region, the gantry crane located in the former Astano in the Fene Shipyard. The works give continuity to those...

Rueda claims in Narón the support of the Xunta de Galicia for SMEs and advanced manufacturing centres

The President of the Xunta de Galicia, Alfonso Rueda, claimed yesterday, during a visit to the facilities of the Galician Consortium of Thermal Treatments (Cogaltra) plant in Narón, the support of the regional administration to small and medium enterprises, as well as to advanced manufacturing centres.

Intaf activates in Narón its unique steel parts treatment centre in Spain

Alfonso Rueda celebrates a project that will serve “200 companies in Galicia”. The Intaf Group has already started up its centre for the treatment of large steel parts. It is a unique infrastructure in Spain. The main feature of the manufacturing centre is a system of furnaces in which an investment of more than 2.6 million euros has been made (80% financed by the Xunta de Galicia through the Igape).

Contact form

Location

Estrada de Cedeira 199

Estrada de Cedeira 199

15570 – Narón (A Coruña) – Spain

Tel. +34 981 397 090

sincromecanica@sincromecanica.es

Estrada de Cedeira 199

Estrada de Cedeira 199

15570 – Narón (A Coruña) – Spain

Tel. +34 981 397 090

sincromecanica@sincromecanica.es