MULTI-SECTORAL ACTIVITY

naval sector

(civilian and military)

industrial

sector

energy

sector

aeronautical

sector

port

sector

Industrial sector

- Iron and steel industry.

- Mining.

- Earthmoving.

- Public works.

- Metal transformation.

- Wood, paper and derivatives.

- Plastics.

- Production, storage and distribution of gases.

- Tool and die making.

- Equipment and components for socio-cultural infrastructures.

Energy Sector

Conventional Energies

- Thermal power stations and their auxiliary installations.

- Combined cycle.

- Liquefied Gas Storage Plants.

Renewable energies

- Wind energy.

- Sea Energies.

- Biofuels.

- Hydroelectric Energy.

Aeronautical sector

- Machining work.

Port sector

- Industries and factories located in port facilities.

- Consignees and Port Operation.

- Port, Fixed and Mobile Installations.

- Elaboration and application of maintenance plans.

- Start-up of plants.

- Conveyor belts.

- Port and container cranes, transtainers, spreaders.

- Bridge cranes.

- Installation/repair of rails and crane runways.

- Warehouses, silos, containers, ramps.

Presentation

NEODYN was founded in 2004, with its origin being the provision of a specialised engineering, technical consultancy and project management service, thus closing the value chain to which the business group in which it is integrated directs its activity.

Likewise, NEODYN is constituted as the entity destined to develop the corporate services of the group, these being integrated by all the functional areas of support to the primary functions.

People are the most important asset of NEODYN and the INTAF GROUP. Their professional capacity, involvement and commitment are the differentiating element on which we focus our efforts.

Availability and dedication are inherent characteristics of our human resources, ensuring an optimum level of flexibility and agility of service.

Our social responsibility policy is aimed at guaranteeing decent working conditions that favour occupational health and safety and the human and professional development of our people. Knowledge management is a key element of our strategy.

Technical consultancy

WELDING

- Analysis of methods.

- Implementation of quality systems.

- Standardisation.

HUMAN RESOURCES

- Human resources training.

- People certification management.

PROCESS DESIGN

- Analysis and improvement of processes.

- Identification and interpretation of contractual, legal and regulatory requirements.

- Participation systems: Suggestion systems, working groups, etc.

- Failure analysis.

- Management of non-conformities.

- Balanced scorecard.

- Periodic inspection and control of working conditions.

MANAGEMENT SYSTEMS

- Quality management systems.

- Environmental management systems.

- Occupational risk prevention management systems.

- Integrated management systems.

Engineering

MAINTENANCE

- Development of maintenance plans and guidelines.

- Development of operational techniques and methods.

- Development of manuals and procedures.

- Maintenance re-engineering.

- Maintenance audits.

WELDING

- Development of welding procedures.

- Qualification in welding procedures.

- Development and implementation of practical guides, technical notes, instructions, etc. for the execution of welding operations.

- Development of construction strategies.

- Design of welded joints.

MECHANICAL AND ELECTRICAL

- Preliminary studies: Preliminary projects and feasibility studies.

- Basic and detailed engineering.

Project management

TESTS

- Calibration.

- Management of Technological Tests: Monographic, corrosion, weldability, chemical composition, fatigue, etc. tests.

- Management of mechanical tests: Tensile tests, bending tests, hardness tests, resilience tests, etc.

- Management of non-destructive tests: Radiographic, ultrasonic, magnetic particle, liquid penetrant, visual inspection, etc.

INSPECTION

- IInterpretation of applicable requirements.

- Development and implementation of inspection programmes.

- Development and implementation of inspection guidelines.

- Management of product and system certification.

- Management of CE certification by certified bodies.

- Management of regulatory inspections.

- Technical inspection of products and systems.

- Analysis and management of non-conformities.

PROJECTS

- Project planning.

- Process control and monitoring.

- Project management systems.

- Start-up of Biodiesel Plants and Combined Cycle Power Plants.

Capabilities

- Trained and specialised human resources.

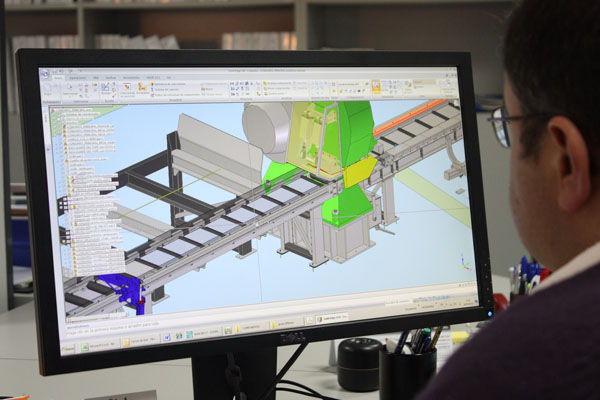

- Computer-aided design for the modelling of assemblies and mechanical parts in 2D, 3D and the production of drawings.

- Customer support in the search for the technical solutions best suited to their needs.

- Finite element calculation (FEM). Allows support for modelling, design and validation of ideas by analysing stresses and deformations in designs.

- Enterprise Resource Planning (ERP) to support all processes and functions.

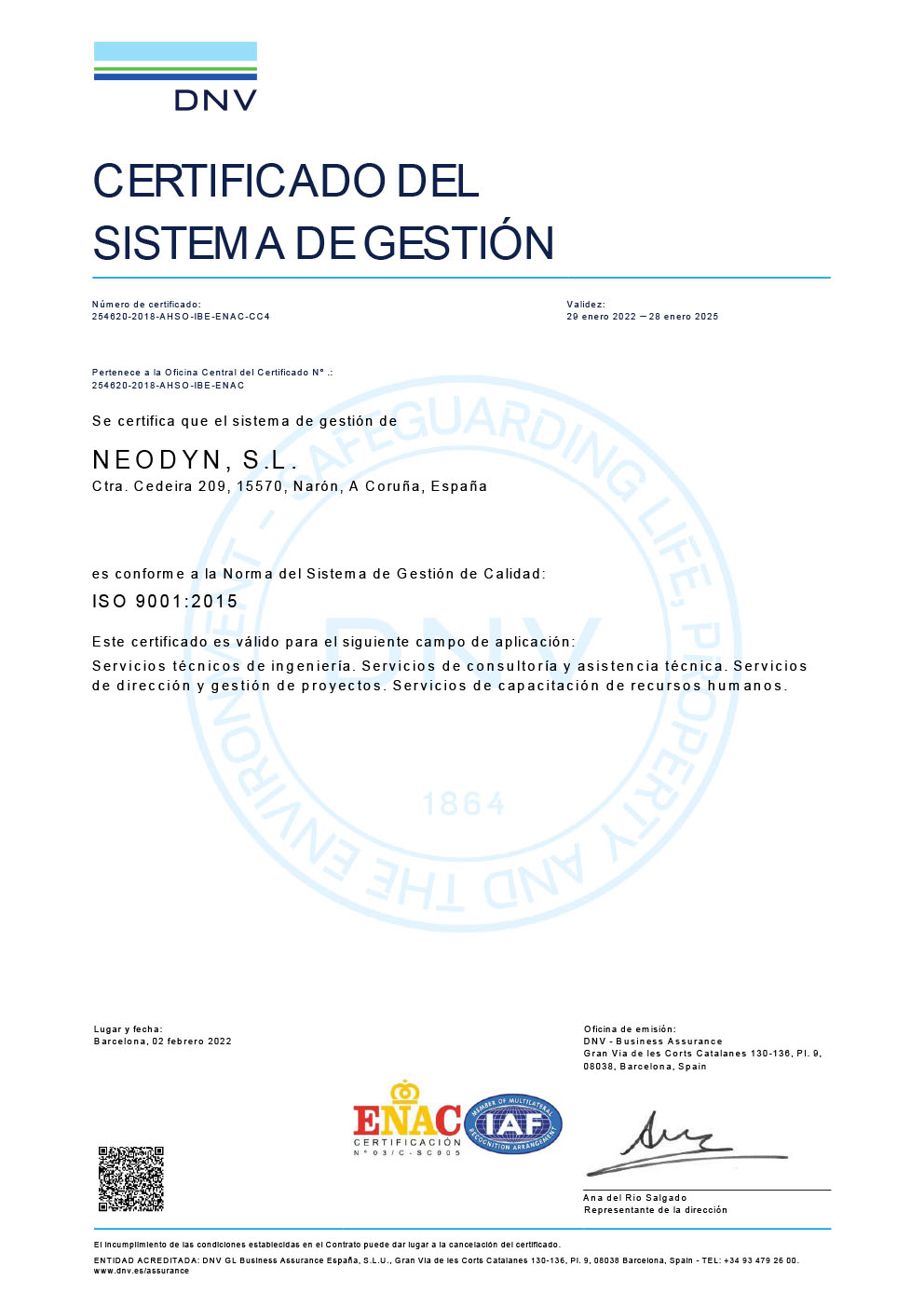

Accreditations

Convinced of the importance of innovation and the optimisation of management efficiency and effectiveness, and applying a firm focus on the customer and processes, NEODYN has developed and implemented a Management System in which three core aspects of the activity coexist in an integrated manner: quality, environment and occupational risk prevention.

This system has been developed based on the following standards

- UNE-EN ISO 9001

- UNE-EN ISO 14001

- OHAS 18001

- It has been certified by Det Norske Veritas, an accredited certification body.

- NEODYN is registered in the Register of Companies of the General Directorate of Armament and Material.

News

GRUPO INTAF supports the maintenance of an icon of Ferrol and its region in the Navantia Shipyard, the Gantry Crane

Tecman Maintenance and Services, a company belonging to the Intaf Group, collaborates with Navantia in the maintenance of one of the icons of Ferrol and the region, the gantry crane located in the former Astano in the Fene Shipyard. The works give continuity to those...

Rueda claims in Narón the support of the Xunta de Galicia for SMEs and advanced manufacturing centres

The President of the Xunta de Galicia, Alfonso Rueda, claimed yesterday, during a visit to the facilities of the Galician Consortium of Thermal Treatments (Cogaltra) plant in Narón, the support of the regional administration to small and medium enterprises, as well as to advanced manufacturing centres.

Intaf activates in Narón its unique steel parts treatment centre in Spain

Alfonso Rueda celebrates a project that will serve “200 companies in Galicia”. The Intaf Group has already started up its centre for the treatment of large steel parts. It is a unique infrastructure in Spain. The main feature of the manufacturing centre is a system of furnaces in which an investment of more than 2.6 million euros has been made (80% financed by the Xunta de Galicia through the Igape).

Contact form

Location

Estrada de Cedeira 209

Estrada de Cedeira 209

15570 – Narón (A Coruña) – Spain

Tel. +34 981 397 142

neodyn@neodyn.es

Estrada de Cedeira 209

Estrada de Cedeira 209

15570 – Narón (A Coruña) – Spain

Tel. +34 981 397 142

neodyn@neodyn.es